redear

Active member

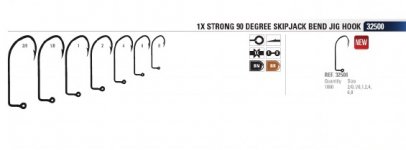

so you have the head pressed and also the hook slot, now you need to make the sprue area where the lead flows into the cavity, I use a piece of a tiny drill bit taped down with the cellophane tape to press the verticle sprue inlet, I sand those bulges out, reinstall my pins and then I take a countersink cutter shaped like a cone mount it in my drill press and cut a countersunk hole where my lead pot nipple will fit down into when pouring. after doing this I take what is called an end mill bit of half inch diam. and mount it to my milling machine, and shave the area down where the jighooks bend will rest, I do this on both halves of the mold and then I put a 1/8 inch end mill bit in the milling machine and shave the area down where the jighooks eyelet will rest. these are just nice touches that makes the mold easier to use because we all know every hook in the box is not the same as far as eyelet height and bend etc. so I hog those areas out, do it mold shaves these areas down too, I guess you could call them recesses. now you are ready to pour your first head, yes you can use the long pins but they will be hard to separate the mold halves, but for the first pour I use the long pins. after checking the first poured head and I'm satisfied, I make a set of short pins for the mold, these pins are only long enough to go into the other mold half maybe 3/16 inch and I round the ends to make the mold halves go together and come apart easily, but also when the halves are together they should not move, this is accomplished my adjusting how much of the pin is sticking out from the mold half, I tap those pins in or out of their mold half that they will be permanently inserted into.